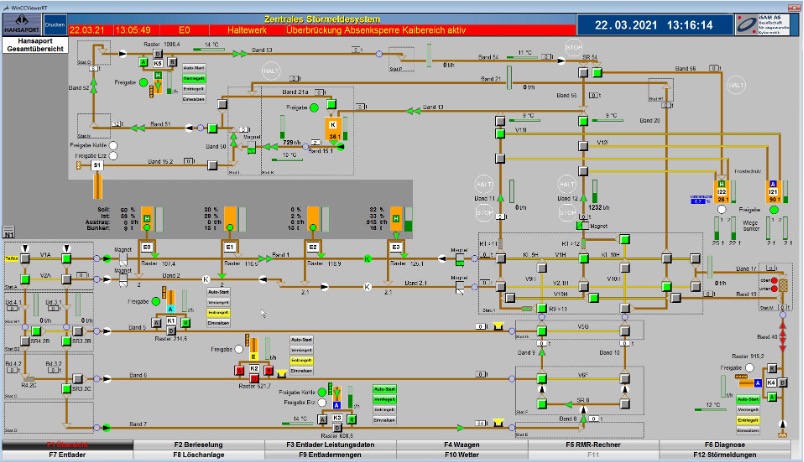

The only fully automated bulk cargo port in the world!

HANSAPORT’s entire process chain is automated. From unloading on the waterside through storage in our storage spaces to delivery on freight trains or inland vessels.

But that is no reason to rest on our laurels. HANSAPORT is constantly working on new technologies and systems for an even more efficient and powerful process.

Technology development

2021

Continuous adaptation to new technologies and scanner types

2018

Development of client portal for communication along the supply chain

learn more

2015

Automation of the inland vessel loader

learn more

2009

Automation of Grab Ship Unloaders

learn more

2005

Automation of individual bulk handling machinery

learn more

2002

Automation of train loading

learn more

2000

Start of automation

1977

Commissioning

1974

Foundation

Automation of train loading

- Positioning of the wagons with 4 x 2D laser scanners per track

- Fully automatic control of the locomotives (no remote control)

- Automated loading of trains on two tracks under the supervision of the signalman (EBA regulation, formerly signalman and two operators)

Automation of the Stockyard Machines

- First use of 3D scanners and GPS for automated bulk cargo handling

- Today, up to 5 stockyard machines are operated in parallel by the central operator

Automation of the Grab Ship Unloaders

- World’s first automatic operation on the waterside (ship-to-shore)

- Simultaneous monitoring of up to 4 unloaders by one operator in the control station

Automation of the Inland Vessel loader

- Loading without operator on site

- Automatic tilt compensation (starboard/port)

- Trimming (bow/stern) without operator intervention for standard loads

Disposition

- Direct transfer of order data from disposition to the bulk handling machinery

- Automated data exchange with the railroad

- Train sequence, load limits of the wagons and specific specifications of the route

- Transfer of wagon weights (calibratable connection of the weighing systems)

- Complete integration of order planning, loading and invoicing

Intelligent networking of bulk handling machinery

- Intelligent, autonomous coordination of the individual machines; if, for example, the train loading system detects a defective wagon, the delivery rate of the stockyard machines is automatically reduced

- Accurate scales (e.g. hopper scales, calibrated scales on the S1) automatically calibrate inaccurate wagons on the stockyard machines

- Conveyor routes can already be used for the next material while the last wagons of the current material are being loaded. The subsystems are coordinated in such a way that material mixing is reliably avoided

Integration of customers

- Online disposition by the customer, adjustments to orders until shortly before fullfilment

- Online customer access to storage data (stockpile model)

- Online tracking of order processing

- Creation of a web interface for communication along the supply chain